When a manufacturer discovers a batch of defective parts, they don’t just throw them out and move on. That’s a correction-a quick fix. But if they want to stop the problem from happening again, they need a corrective action. This isn’t guesswork. It’s a structured, documented process used by companies from medical device makers to automotive suppliers to cut defects, avoid recalls, and pass audits.

What’s the Difference Between a Correction and a Corrective Action?

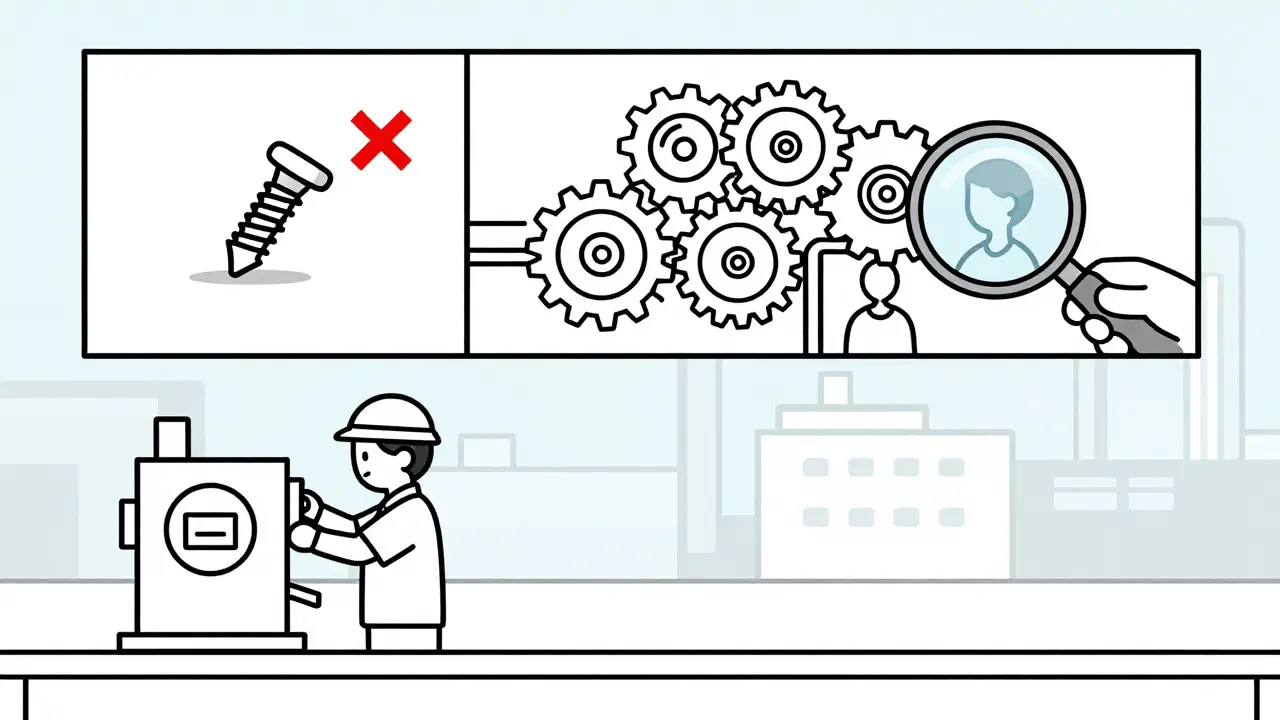

Think of it this way: if a machine keeps making screws that are 0.1mm too long, a correction is adjusting the setting right now to fix the next batch. Simple. Fast. But if you don’t figure out why the machine drifted off spec in the first place-maybe the sensor is worn, or the operator isn’t trained-you’ll be fixing the same thing next week. Corrective action digs deeper. It’s about finding the root cause and making sure it never happens again. The FDA and ISO standards require this. In medical device manufacturing, skipping this step can lead to warning letters, production halts, or worse. A 2022 FDA review found that 61% of companies failed CAPA audits because they only corrected symptoms, not causes.The Six-Step Corrective Action Process

Every solid corrective action follows the same six steps. It’s not magic-it’s method.- Identify the problem: It starts with data. A rejected part. A customer complaint. A machine alert. Quality teams use control charts, inspection logs, or automated sensors to flag issues. On average, a single quality event takes 2.3 hours just to document.

- Evaluate and categorize: Not all problems are equal. Is this a safety risk? A regulatory violation? A minor cosmetic flaw? High-risk issues get immediate attention. In pharmaceuticals, a deviation that affects potency triggers a full CAPA. A scratch on a pill bottle might just get logged.

- Find the root cause: This is where most fail. The 5 Whys method is common: Why did the screw fail? Because the tool wore out. Why? Because it wasn’t replaced on schedule. Why? Because the maintenance log wasn’t updated. Why? Because no one was assigned to check it. Why? Because there was no accountability. Fishbone diagrams also help map out people, machines, materials, methods, and environment.

- Plan the fix: A good Corrective Action Plan (CAP) has four parts: specific actions (e.g., “replace sensor model X by March 15”), clear deadlines, named owners (not “the team”), and how success will be measured. No vague language like “improve process.”

- Implement the solution: This isn’t just paperwork. It’s training staff, updating SOPs, recalibrating machines, or redesigning a fixture. The solution must be tested. For process changes, manufacturers typically validate with at least 30 samples to ensure statistical reliability.

- Verify effectiveness: Did it work? Check defect rates over the next three production cycles. If the defect rate dropped from 2.8% to 0.4%, you’ve got proof. If it’s still at 2.1%, you missed the root cause. Verification must be documented and auditable.

Why Most Corrective Actions Fail

It’s not because people are lazy. It’s because the system is broken. A 2023 Dozuki survey found that 57% of failed CAPAs had shallow root cause analysis. Companies jump to “operator error” because it’s easy. But operators don’t make mistakes in a vacuum. Was the training outdated? Were the instructions unclear? Was the tool broken? The real cause is often hidden in the system. Another big issue: documentation overload. One Reddit user in quality assurance reported that a single CAPA generated 47 pages of paperwork. That’s not compliance-it’s resistance. Teams delay or skip steps because they’re drowning in forms. And then there’s accountability. If no one is clearly named as responsible, the action gets pushed to the next meeting. And the next. And the next.What Works: Real-World Success Stories

The best manufacturers don’t treat CAPA as a compliance chore. They treat it as a performance lever. An Australian automotive supplier cut defect rates from 2.8% to 0.4% in 18 months by integrating CAPA with their production line sensors. When a torque wrench went out of spec, the system auto-generated a CAPA, assigned it to maintenance, and tracked completion in real time. They reduced documentation time by 41% using digital tools. A medical device maker in the U.S. saw a 34% drop in regulatory scrutiny after overhauling their CAPA system. They assigned a single owner per CAPA, set 7-day deadlines for root cause analysis, and used statistical process control charts to verify results. Auditors noticed the difference. In both cases, the key wasn’t more staff. It was better tools and clearer ownership.Technology Is Changing the Game

Old-school CAPA relied on spreadsheets and printed forms. Now, digital systems are making it faster and smarter. AI-powered tools can scan thousands of defect reports and flag patterns humans miss. One manufacturer reduced root cause investigation time by 52% using machine learning to link machine vibrations to part failures. Blockchain-backed audit trails are being piloted by 41% of medical device firms, per AdvaMed. These systems lock in who did what, when, and why-making audits faster and fraud impossible. Gartner predicts that by 2027, 65% of manufacturers will use predictive CAPA systems. These systems don’t wait for a defect. They analyze real-time data-temperature spikes, motor load, cycle times-and trigger corrective actions before the part even leaves the machine.

Who Needs CAPA? And Who Doesn’t?

Not every factory needs a full FDA-style CAPA system. Medical device makers? Mandatory. ISO 13485 requires it. Pharmaceuticals? Required under cGMP. Automotive? IATF 16949 demands it. These industries have high stakes: patient safety, recalls, fines. But what about a small shop making custom metal brackets? If they have only 2-3 defects a month and no regulatory pressure, a simple correction log with a weekly review might be enough. Over-engineering quality systems can drain resources without adding value. The rule of thumb: if a mistake could hurt someone, cost you a recall, or get you shut down by regulators-then you need CAPA. If it’s just an annoyance? Fix it, learn from it, move on.How to Start Getting It Right

If you’re starting from scratch, here’s how to avoid the traps:- Start small. Pick one recurring defect. Fix it properly. Document it. Prove it worked.

- Assign one owner per CAPA. No committees. No “team responsibility.”

- Use digital tools. Even a simple cloud-based form system beats paper. Reduces delays and lost files.

- Measure success by defect reduction-not paperwork completed.

- Train everyone. Operators, engineers, managers. If they don’t understand why CAPA matters, they’ll skip it.

Josh josh

man i just fixed a screw issue at my shop last week and i didnt even know this had a name

we just called it 'fix it before the boss notices' lol

bella nash

The structural integrity of industrial quality assurance protocols necessitates a rigorous epistemological framework grounded in empirical verification. The conflation of corrective measures with systemic remediation represents a fundamental ontological error in operational governance.

George Rahn

This is why America still leads in manufacturing. We don’t pussyfoot around with 'maybe the operator messed up' nonsense. We find the root cause, we fix it, and we make sure the next guy doesn’t get a free pass. You want to know why our stuff lasts? It’s because we don’t let laziness wear a badge. Other countries? They paper over problems till the whole damn factory collapses. We don’t do that here.

Simran Kaur

This made me tear up a little honestly

My uncle works in a small medical parts plant in Punjab and he told me they used to just throw away defective valves till someone trained them on 5 Whys

Now they’ve cut waste by 70% and the workers feel proud

It’s not just about audits-it’s about dignity

Joanna Domżalska

You’re telling me we need 6 steps to fix a screw that’s 0.1mm too long? What a joke. This is corporate theater. They call it 'corrective action' so they can charge consultants $200k to write a 47-page PDF no one reads. Real manufacturers just turn the knob and move on.

Mohammed Rizvi

I’ve seen this play out in 3 factories. The ones with digital CAPA systems? They’re the ones with happy engineers. The ones with binders and pen-and-paper? The staff are either burned out or actively sabotaging the process. One guy told me he 'accidentally' lost the CAPA form every time it came due. No surprise they never fixed anything.

eric fert

Let’s be real-this whole CAPA thing is just a way for middle managers to feel important while doing absolutely nothing productive. You spend 2.3 hours documenting a problem, then another 14 hours in meetings debating who’s to blame, then you wait 3 weeks for 'approval' to replace a $12 sensor. Meanwhile, the machine is still making junk. The real root cause? Management doesn’t want to spend money. So they invent processes to pretend they’re fixing things. It’s not quality control. It’s performance art.

Curtis Younker

This is the kind of stuff that changes lives. Not because it’s fancy or high-tech-but because it gives people the power to fix things. I’ve seen line workers who used to feel like cogs turn into problem-solvers because someone finally said 'Hey, you see this? You own it.' That’s not a process. That’s a revolution. And it starts with one person saying 'I’m not just fixing a part-I’m fixing the system.' You can’t measure that in defect rates. But you can feel it in the air.

Shawn Raja

You know what’s funny? The same people who scream about 'over-engineering' when it’s a screw problem? They’re the first to demand a 12-step CAPA when a patient gets a slightly mislabeled vial. We treat a $0.50 screw like it’s a nuclear reactor and a $5000 medical device like it’s a garage sale find. The real problem isn’t the process. It’s the brain that thinks quality is a checklist, not a mindset.

Ryan W

ISO 13485 requires CAPA? That’s why US manufacturing is dying. Compliance-driven culture kills innovation. You want to cut defects? Stop auditing and start innovating. Let engineers build better machines-not write SOPs about why the last one broke. The real enemy isn’t operator error. It’s bureaucracy dressed up as quality.

Allie Lehto

I just had to do a CAPA for a typo in a label. 47 pages. My boss said 'this is for the audit.' I said 'but no one will ever read it.' He said 'exactly.' I quit that job last week. I’m not spending my life making fake paperwork to prove we care about things we don’t care about. #CAPAisacult